LATEST NEWS

King Reintroduces Bipartisan Bill that Supports Trucking Workforce of the Future

Legislation will grow career opportunities for young drivers and enhance safety training in the trucking industry.

WASHINGTON, D.C. – U.S. Senator Angus King (I-Maine) is reintroducing the Developing Responsible Individuals for a Vibrant Economy (DRIVE-Safe) Act, a bipartisan bill that aims to address the driver shortage in the trucking and logistics industry and enhance safety training and job opportunities for young truckers. Though 49 states and the District of Columbia allow individuals to obtain a commercial driver’s license (CDL) at the age 18, federal law currently prohibits those operators from moving goods from state to state until they are 21. The DRIVE-Safe Act establishes an apprenticeship program that would allow for the legal operation of a commercial motor vehicle in interstate commerce by CDL holders under the age of 21.

“The trucking and national supply chain network have been fundamental to America’s response to the coronavirus, moving goods to support medical personnel and sustain the public throughout this crisis,” said Senator King. “The industry is vital to our everyday life, but driver shortages threaten its future. The DRIVE Safe Act addresses these challenges by creating an apprenticeship program that works across state lines, enhances the skills of our workforce, and helps train the next generation of safe drivers. I’m proud to once again stand with my bipartisan group of colleagues to introduce this bill, and hope that the Congress will move on this commonsense solution to a pressing problem.”

The apprenticeship training program would help ensure these drivers are trained beyond current standards while instituting rigorous safety standards and performance benchmarks. The apprenticeship program established by the DRIVE-Safe Act would require young drivers to complete at least 400 hours of on-duty time and 240 hours of driving time with an experienced driver in the cab with them.

All trucks used for training in the program must be equipped with safety technology including active braking collision mitigation systems, a video event capture system, and a speed governor set at 65 miles per hour or below.

In addition to Senator King, the legislation is supported by U.S. Senators Todd Young (R-Ind.), Jon Tester (D-Mont.) Tom Cotton (R-Ark.), Jim Inhofe (R-Okla.), Joe Manchin (D-W.V.), Jerry Moran (R-Kan.), and Kyrsten Sinema (D-Ariz.).

Lumber Prices Are Soaring. Why Are Tree Growers Miserable?

Saw mill operators harvest gains while Southern landowners struggle with tree surplus; ‘I’m not making anything’

By: Ryan Dezember and Vipal Monga | Photograph by: Charlotte Kesl for The Wall Street Journal

Mr. Hopkins raises timber on a 25-year rotation to support himself and make payments to more than a dozen shareholders in the 109-year-old family business. Photo by: Charlotte Kesl for The Wall Street Journal

TWIGGS COUNTY, Ga.—The pandemic delivered an unexpected boon to the lumber industry. Hunkered-down homeowners remodeled en masse and low mortgage rates drove demand for suburban housing. Lumber supplies tightened up and prices smashed records.

“You must be making a lot of money,” an Ace Hardware store manager told timber grower Joe Hopkins, whose family business has about 70,000 acres of slash pine near the Okefenokee Swamp.

“I’m not making anything,” Mr. Hopkins replied.

Timber growers across the U.S. South, where much of the nation’s logs are harvested, have gained nothing from the run-up in prices for finished lumber. It is the region’s saw mills, including many that have been bought up by Canadian firms, that are harvesting the profits.

Saw mills are running as close to capacity as pandemic precautions will allow and are unable to keep up with lumber demand. The problem for timber growers is that so many trees have been planted between the Carolinas and Texas that mills are paying the lowest prices in decades for logs.

The log-lumber divergence has been painful for thousands of Southerners who are counting on pine trees for income and as a way to hold on to family land. And it has been incredibly profitable for forest-products companies that have been buying mills in the South. Three Canadian firms— Canfor Corp. CFPZF -0.30% , Interfor Corp. IFP 4.43% and West Fraser Timber Co. WFG 2.07% —control about one-third of the South’s lumber-making capacity. Since bottoming out last March, shares of the Canadian sawyers have risen more than 300%, compared with a 73% climb of the S&P 500 index.

The surplus of standing pine is such that growers, foresters and mill executives expect that even with mills sawing at capacity and new facilities coming online, it could be another decade, maybe two, before enough trees are felled to balance supply with demand.

Meanwhile, it’s a buyer’s market for logs down South, said Don Kayne, Canfor’s chief executive. “We try to be fair,” he said.

At their onset, coronavirus lockdowns seemed to derail the housing recovery. Lumber prices plunged in March 2020. Dealers liquidated inventories. Speculators dumped lumber futures and took short positions, betting prices would fall further. Mills sent workers home and curtailed production. By April, roughly 40% of North America’s saw mill capacity was shut down.

Wood was in short supply when the remodeling bonanza began. Then the housing market picked up. Restaurants around the country had to build outdoor decks. Saw mills ramped up to capacity but couldn’t catch up. By last summer, lumber was America’s hottest commodity.

Lumber futures, a benchmark for an array of regional and species-specific prices, rose to a record in early August and kept climbing. Futures contracts traded up to $1,000 per thousand board feet, more than 50% above the previous high, set during the 2018 building season.

Diverging Markets

While lumber prices have set records this year, prices of the timber used to make lumber have remained low.

Home builders kept hammering through mild early-winter weather and depleted lumber dealers are stocking up for spring. Lumber futures have hit new all-time highs and are more than twice the typical winter price. Spot prices for southern yellow pine set records in January.

None of that has lifted the price of timber, which never recovered from the 2007 housing bust. Logs for softwood lumber averaged $22.50 a ton across the South last summer, the least since 1992, according to TimberMart-South, a pricing service affiliated with the University of Georgia’s forestry school.

“If you put inflation on it, it’s really sad,” said Mr. Hopkins, the Georgia timber grower. Adjusted for inflation, prices for the logs used to make lumber are at their lowest in more than 50 years.

Chairman David Scott Welcomes Senate Approval of Secretary Tom Vilsack to Lead USDA

House Agriculture Committee Chairman David Scott issued the following statement in response to the Senate approving Tom Vilsack to lead the United States Department of Agriculture (USDA):

“I applaud the Senate for approving Secretary Tom Vilsack to head the Department of Agriculture for a second time. I am excited about working with him and his staff to ensure that USDA works to support our farmers in an equitable way. I look forward to Secretary Vilsack joining us at our House Agriculture Committee hearings over the course of his tenure to provide critical updates on the important work of USDA.”

1301 Longworth House Office Building | 202-225-2171 | agriculture.house.gov | @HouseAgDems

John Deere Unveils Its Powerful, Purpose-Built 768L-II Bogie Skidder

John Deere expands its skidder lineup with the new 768L–II Bogie Skidder, a purpose–built machine designed to navigate wet and steep slope conditions.

The 768L–II features heavy–duty bogie axles, outstanding tractive ability and floatation, increasing durability and performance in challenging conditions. Additionally, a new arch design expands visibility while a long wheelbase and improved boom–arch envelope increase dexterity and maneuverability in the woods, significantly boosting productivity and performance.

The bogie skidder incorporates the customer–favorite features found in the L–II machines, including a comfort–boosting cab, redesigned electrical and hydraulic systems, and industry–exclusive Continuously Variable Transmission.

John Deere introduces the new six–wheel 768L–II Bogie Skidder, a true woodland warrior designed to conquer wet conditions and steep slope terrain. Incorporating the proven, durable features found on the John Deere L–II Skidder lineup, the new 768L–II maximizes productivity, performance, and comfort when carrying hefty loads over long distances in challenging conditions.

"Profitability and productivity are critical in the woods, and as loggers take to new areas for jobs, they need dependable machines that are built with these niche applications in mind," said Matthew Flood, product marketing manager, John Deere. "With our new 768L–II Bogie Skidder, we're delivering a purpose–built machine that navigates tough terrain, such as swamps or steep slopes. Providing distinct features, the John Deere bogie skidder helps loggers maximize their potential, regardless of the conditions."

The 281–horsepower 768L–II features heavy–duty bogie axles, which incorporate large components to maximize durability and stability for long axle and tire life. The heavy–duty axles are purpose–built for tough applications, effortlessly pulling heavy loads and maneuvering tough terrain. The smooth, stable operation results in reduced machine vibration, ultimately minimizing operator fatigue. Another key feature is the excellent tractive ability and floatation. When combined with the bogie axles, ground pressure is reduced, allowing the 768L–II to work in wet terrain not accessible with a four–wheel skidder. As a result, the harvesting window is extended, adding more working days to the calendar.

The new arch design provides the operator with an expansive rearward view of the grapple and work area, providing excellent visibility. Improving maneuverability, the long wheelbase and boom–arch envelope boost reach and lift capability for the boom and grapple, increasing dexterity in the woods. The tight turning radius enhances agility at the landing.

"The John Deere bogie skidder is hands down twice as good as a regular four–tire skidder. It's just all–around better in my book for productivity and ground disturbance," said Jason Dawson of Triple J Logging. "With the 768L–II, you can carry twice as much of a load, especially in wet conditions and on the steep terrain, without tearing the ground up."

The 768L–II retains the other customer–favorite features introduced on the L–II product lineup. Streamlined and redesigned electrical and hydraulic systems result in improved uptime and increase guarding and protection of key components. An increased grapple squeeze force and two–speed winch further increase productivity, while articulation steering sensors improve the operator experience.

Highly regarded by customers, all L–Series II models feature a spacious cab, including ample storage space, configurable controls, and an effective HVAC system. Armrest–mounted electrohydraulic controls offer accessible, hand–finger operation of all machine functions, and joystick steering provides smooth control of steer, direction, and ground speed. The industry–exclusive Continuously Variable Transmission (CVT) marries the efficiency of a direct–drive transmission with the smoothness of a hydrostatic drive. As a result, CVT provides more power to the ground by sensing the load, increasing torque and tractive effort as needed to maintain the desired speed.

To learn more about the updated 768L–II Bogie Skidder, as well as the full line of John Deere Forestry equipment, visit www.JohnDeere.com or your local John Deere dealer.

John Deere Unveils Its Precision Forestry Technology Initiative

MOLINE, IL (Feb. 17, 2021) – In response to customer needs, John Deere announces its Precision Forestry initiative, a focused approach to its job site technology solutions. Through Precision Forestry, John Deere is reorganizing its technology portfolio and doubling down on its efforts in delivering solutions designed to increase efficiency and productivity in the woods. The shift to Precision Forestry aligns with the brand’s overarching Smart Industrial operating model, through which John Deere aims to deliver increased customer value by focusing on three core areas: Production Systems, Technology Stack and Lifecycle Solutions.

“Previously, the industry has focused on developing bigger, faster, more powerful machines to boost performance, but larger machines sometimes present more challenges, especially on job sites with limitations,” said Matthew Flood, product marketing manager, John Deere. “Technology has been a gamechanger for the forestry industry, enabling us to improve operator efficiency and performance without altering machine size. With the Precision Forestry initiative, we’re organizing our portfolio to create a foundation for the future of forestry machines and job site technology.”

Precision Forestry is a more descriptive term for what customers can expect from the John Deere technology suite, including real-time, map-based production planning and tracking capabilities along with new and evolving operator assistance capabilities. This new alignment lays the groundwork for the future of technology solutions, as John Deere builds in these core areas to help customers work faster and smarter on the job site. For customers, the new Precision Forestry direction will simplify the John Deere technology portfolio, making it easier to select and adopt customized solutions based on their unique job site needs.

“With technology, we believe that loggers need to embrace working smarter, not harder. The logging industry is built on hard work – it’s part of the industry’s DNA. We want to complement that work ethic with machine intelligence and system-level integration, delivering the tools loggers need to increase efficiency and performance in the woods,” said Flood.

To learn more about the Precision Forestry technology offerings, as well as the full line of John Deere Forestry equipment, visit http://www.johndeere.com/forestry or a local John Deere dealer.

About John Deere

Deere & Company (www.JohnDeere.com) is a world leader in providing advanced products, technology and services for customers whose work is revolutionizing agriculture and construction — those who cultivate, harvest, transform, enrich and build upon the land to meet the world's increasing need for food, fuel, shelter and infrastructure.

Contact:

Amy Jones,410-821-8220, amyj@imre.com

Innovation in Forestry – Tigercat Featured on Forestry Virtual Event Feb. 18th

CM Labs Simulations, developer of Vortex® training simulators, entered into a partnership with Tigercat Industries earlier this year.

February 1, 2021 — CM Labs Simulations, developer of Vortex® training simulators, will be hosting a virtual event on February 18, featuring live and on-demand presentations and demos devoted to the latest innovations in the forestry and logging sector.

“This event is designed to provide the industry with new tools and information to support productivity in training and operations,” says Drew Carruthers, CM Labs’ Director of Product Management and Strategic Partnerships.

In addition to CM Labs, the speaker line-up includes Tigercat Industries, leader in the design and manufacture of premium quality forest harvesting systems. It also includes the Mont-Laurier Vocational School, an educational institution in Quebec (Canada) that produces some of the most skilled operators in the region.

Along with thought leadership, the event will feature one-on-one access to technology and training professionals, virtual networking opportunities, and new product demos. Just as in a live event, participants will have access to experts to discuss their projects immediately if need be.

Attendees will obtain actionable insights into the latest advances in logging operations, and be among the first to discover new training solutions for forestry equipment operators.

The February 18th event features sessions on:

How to advance forestry training with technology – CM Labs Simulations

Innovation in forestry – Tigercat Industries

New simulator training packs (forwarder and harvester solutions) – CM Labs Simulations

The future of forestry training – Mont-Laurier Vocation School

Presentations will also be available on-demand following the event.

About CM Labs Simulations Inc.

CM Labs’ mission is to simulate the world to make operations safe and efficient, by connecting people, processes, and equipment design.

The company builds simulation-based solutions to help clients design advanced equipment and prepare for skilled operations. Through its Vortex Studio platform, CM Labs provides capabilities for training simulators, mission rehearsal, virtual prototyping, and testing. CM Labs’ vision is to be the leader in digital transformation, from machine design to training.

Clients include OETIO, IUOE, Kiewit, Liebherr, Mammoet, Manitowoc, NASA, and over 100 other world-class companies, OEMs, equipment operators, and trades training organizations.

Vortex® is a registered trademark of CM Labs Simulations.

For more information, contact info@cm-labs.com, or visit www.cm-labs.com.

John Deere Forestry Tech Panel: Feb. 17th at 8:00PM EST

Explore the benefits and challenges of technology for your business with John Deere.

The forestry industry is evolving, and technology opens the door to new opportunities and increased productivity and efficiency on the job site.

Join us for a virtual panel discussing the impact of technology on the forestry industry on Wednesday, Feb. 17, at 8 p.m. EST. Hosted by John Deere and moderated by the American Loggers’ Council, we’ll speak with loggers from across North America about their experiences with technology and how they see the industry evolving in the future.

During this discussion, we will cover:

How loggers are using technology on the job site and the value it provides

Considerations to keep in mind when evaluating new solutions for your business

The benefits and challenges of technology

Our panelists’ predictions for how technology will change the industry

Changing Highway Truck Weight Limits Can Be Safer for Everyone

Truck weight limits are a frequent topic of policy debates in the forest industry. All too often, the discussion is devoid of facts and analysis and full of emotional appeals. The industry asserts that moving loaded trucks onto the Interstate Highway System will be safer and more efficient. At the same time, some safety advocates counter that heavy trucks on the highway must pose a danger.

Fortunately, there is data to help us understand what changing truck weights can do for road safety. Section 194 of the Consolidated Appropriations Act of 2010 (Public Law (P.L.) 111-117) directed the Secretary of Transportation to study the impacts of the Maine and Vermont truck pilot programs, which replace federal commercial-vehicle weight regulations with state limits on interstate highways in those states. In Maine, that means allowing trucks up to 100,000 pounds gross vehicle weight on six axles onto the federal highway. In Vermont, the federal highways matched state limits of a maximum gross vehicle weight of 99,000 pounds on six axles.

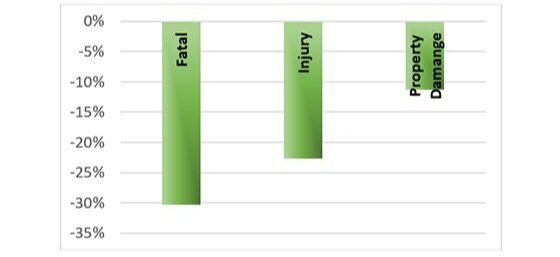

It has been over a decade since that legislation passed, and we can see that roads have gotten safer. Analyzing all accidents involving medium and heavy weight trucks statewide in Maine, we see that the average number of fatal, injury-causing, and property-damage causing accidents decreased when looking at the years before heavier trucks were allowed on the highway (2005-2009iii) and for the years following (2011-2020iv).

Accidents Involving Medium and Heavy Weight (>10,000 lbs.) Trucks, Statewide (Maine)

Change in Maine Statewide Truck Accidents Following Alignment of State and Federal Weight Limits on Interstate Highways

In 2015, the Maine Motor Transport Association(v) conducted a detailed analysis of how the change in truck weight limits on the federal interstate highway in Maine impacted safety and found that after the truck weight change:

There are fewer fatalities involving commercial motor vehicles on Maine roads;

The Interstate Highway (I-95) is safer;

Secondary roads are safer;

The average total number of crashes involving all commercial trucks has reduced by almost 100 (now, in 2021, by over 150); and

There are fewer crashes involving six-axle trucks.

As the forest industry strives to be safe and efficient, it is essential to understand how policy changes can impact others. Due to changing truck weight laws so that the Interstate Highway System matches state law (long an FRA policy priority), Maine’s experience suggests that getting heavy trucks off secondary roads and onto the highway reduces fatalities, injuries, and accidents involving commercial trucks.

Author/Source: Eric Kingsley | FRA Northeast Region Coordinator

i. US Department of Transportation, Federal Highway Administration. Maine and Vermont Interstate Highway Heavy Truck Pilot Program 6-Month Report. https://ops.fhwa.dot.gov/freight/sw/reports

ii. Database query at Maine Department of Transportation, Maine Public Crash Query Tool, https://mdotapps.maine.gov/MaineCrashPublic/PublicQueryStats

iii. The data set begins in 2005, so data on crashes statewide is unavailable for dates before then using this tool.

iv. It appears that the weight change took effect during 2010, so that year’s data has been excluded from both data sets.

Collins, Golden Urge USDA to Distribute COVID-19 Funding for Loggers, Timber Haulers Immediately

The December COVID-19 relief package included $200 million for logging and log hauling businesses

Washington, D.C. — U.S. Senator Susan Collins and Representative Jared Golden led 19 of their colleagues in sending letters to the U.S. Department of Agriculture (USDA) to urge the quick distribution of the $200 million in COVID-19 relief funding for logging and log hauling businesses that was included in the COVID-19 relief package that was signed into law in December.

Last year, Senator Collins and Congressman Golden introduced the Loggers Relief Act to establish a new USDA program to provide direct payments to loggers who have been seriously impacted by the pandemic. Their bill was co-sponsored by Senator Angus King and Congresswoman Chellie Pingree. As a lead negotiator of the COVID-19 relief bill that was signed into law in December, Senator Collins successfully pushed for the inclusion of the Logger Relief Act and $200 million in funding in the final package.

“The plight of our forest products industry has increasingly worsened since March of last year, when the onset of the pandemic crashed global pulp and paper markets and housing starts dwindled,” wrote Senator Collins and Representative Golden. “Given the severity of the situation, many loggers and haulers are facing hard decisions about whether they can afford to keep on in the industry.”

“In order to keep the broader forest products sector operational, we must ensure our loggers and haulers make it through this enormously challenging time,” Senator Collins and Representative Golden continued. “We urge you to quickly implement this critical provision in order to distribute this assistance as soon as possible.”

“Time is of the essence now and we must ensure that these pandemic relief funds for timber haulers and harvesters are distributed quickly and to the businesses they were intended for,” Dana Doran, Executive Director of the Professional Logging Contractors of Maine, said. "This funding will literally be a lifeline for many struggling family logging and trucking firms in Maine and across the country, and it is essential that it be disbursed efficiently and with a minimum of red tape so it can begin having an impact on them and their communities. We thank Senator Susan Collins and Representative Jared Golden for leading the effort to secure this aid and Senator Angus King and U.S. Representative Chellie Pingree for joining that effort."

The logging industry has experienced a steep decline in demand for wood fiber since the coronavirus pandemic began, leading to an estimated 20 percent or more drop in the timber harvest this year. The $200 million in relief funding will go to timber harvesting and hauling businesses that have, because of the COVID–19 pandemic, experienced a loss of 10 percent or more in gross revenue during the period beginning on January 1, 2020, and ending on December 1, 2020, compared to the same period last year. Maine’s logging industry is a linchpin of the state’s economy, generating an estimated $619 million in economic output, and providing $342 million in income to around 9,000 Mainers, most of whom live in rural communities.

Senator Collins and Representative Golden’s letters were signed by Senators King, Cornyn (R-TX), Smith (D-MN), Cassidy (R-LA), Baldwin (D-WI), Burr (R-NC), Wicker (R-MS), Tillis (R-NC), and Representatives Rouzer (NC-07), Palazzo (MS-04), Kelly (MS-01), Timmons (SC-04), Pingree, LaMalfa (CA-01), Tiffany (WI-07), Murphy (NC-03), Guest (MS-03), Kuster (NH-02), and Spanberger (VA-07).

ALC Members: Log Truck Driver Safety Training is Now Included in Your Membership

We are excited to announce that in addition to our exclusive member rebates, access to annual meetings, and being a part of the preservation of logging, log truck driver safety training is now included in your ALC membership. The words “safety training” is often a bit taboo for loggers, but the unfortunate reality is that most loggers are just one wreck and a billboard lawyer away from going out of business. That is why safety training for log truck drivers has never been more important. Thus, ALC members now have access to 30+ online safety training courses that focus specifically on transportation of forest products.

Members can access training courses at any time using a smart-device or computer with internet access. A detailed record of completed courses, the training material used for the training, the date and time completed, and a training certificate is available for each course completed through the online training platform. This information can be made available to insurance companies, business owners, and logger associations. The convenience of “on-demand” driver safety training will save time and money, allowing more time for productivity while complying with governmental and insurance carrier mandates. If you are already a member, please contact us and a link will be provided to you for access.