LATEST NEWS

Tackle demanding forestry processing environments with the Komatsu PC230F-11

September 6, 2022 — Your forestry crews need equipment that can deliver exceptional performance in difficult environments. Control downtime and drive productivity with the robust, dependable and fuel-efficient Komatsu PC230F-11 processor. Delimb and cut and stack timber with this powerful and maneuverable processor, designed specifically to meet the demands of forestry work.

Large trees can be moved more easily thanks to a powerful swing system and a large swing circle. With exceptional reach of up to 29 feet (8,951 mm), the excellent maneuverability of the PC230F-11 helps drive productivity.

Designed with a high and wide undercarriage, powerful swing motor and ability to withstand high-debris conditions, the PC230F-11 is backed by excellent service, easy access to parts and an industry-leading warranty. Built to tackle demanding forestry processing environments, the PC230F-11 has exceptional reach, a high and wide rugged undercarriage and a powerful swing system.

Quick specs for the PC230F-11

Net horsepower: 197 HP (147kW) @ 2,050 rpm

Operating weight: 67,516 lbs. (30,625 kg)

Swing torque: 58,334 ft.-lbs. (8,065 kg-m)

Engineered for high-debris environments

When operators are working in high-debris conditions, the robust wide-fin radiator is protected by heavy-duty forestry screens and a variable pitch reversing fan helps improve airflow.

Offering excellent ground clearance, the PC230F-11, provides reliable maneuverability in tough forestry environments thanks to a high and wide undercarriage designed with larger class-size components.

Operators can adjust quickly to a sudden change in load weight without losing productivity with the Auto Power Max feature. It automatically senses the difference and reacts with a seven-second burst of additional horsepower to help pull the trees through, during the delimbing process.

Operator comfort supports productivity

To reduce operator fatigue, the PC230F-11 provides a quiet, comfortable work environment. Cabs are climate-controlled and equipped with Bluetooth technology. The cushioned air-suspension seat can be heated or cooled.

An extra-rugged exterior protects against falling limbs with a 1.26 inch-thick (32 mm) polycarbonate front window and metal designed to withstand demanding environments. The PC230F-11 features heavy-duty service undercover guards and rear compartment doors, and a right corner guard with a standard tree deflector.

Less refueling

The Komatsu SAA6D107E-3 Tier 4 Final engine is more fuel efficient than the prior Tier 4 interim engines. Thanks to proprietary Komatsu engine technology, the larger size-class (PC290LL-11) factory-installed engine also powers performance.

Your operators can spend more time on the job and less time refueling with the additional fuel storage on the PC230F-11. The tank is in the rear of the carrier and built into the counterweight, delivering double the fuel capacity. Because the fuel tank was moved to the rear, there is a large tool storage area on the side for the operator to store an extra five-gallon bucket of oil, extra chains and other tools.

Learn more about the Komatsu PC230F-11 processor and other Komatsu forestry products.

Media support:

Shawn-Laree O’Neil, 773-802-0377, shawn-laree.o’neil@global.komatsu

About Komatsu

Komatsu develops and supplies technologies, equipment and services for the construction, mining, forklift, industrial and forestry markets. For a century, the company has been creating value for its customers through manufacturing and technology innovation, partnering with others to empower a sustainable future where people, business and the planet thrive together. Front-line industries worldwide use Komatsu solutions to develop modern infrastructure, extract fundamental minerals, maintain forests and create consumer products. The company's global service and distributor networks support customer operations to enhance safety and productivity while optimizing performance.

To learn more, visit www.komatsu.com

# # #

All comparisons and claims of improved performance made herein are made with respect to the prior Komatsu model unless otherwise specifically stated.

Product designs, specifications and/or data in this document are provided for informational purposes only and are not warranties of any kind. Product designs and/or specifications may be changed at any time without notice. The only warranties that apply to sales of products and services are Komatsu’s standard written warranties, which will be furnished upon request.

Komatsu and other trademarks and service marks used herein are the property of Komatsu Ltd. or its subsidiaries, or the respective owners or licensees.

© 2022 Komatsu Ltd. or one of its subsidiaries. All rights reserved.

Forestry Mutual Insurance Credit Rating Upgraded by AM Best

AM Best has upgraded the Financial Strength Rating to A- (Excellent) from B++ (Good) and the Long-Term Issuer Credit Rating to “a-” (Excellent) from “bbb+” (Good) of Forestry Mutual Insurance Company (FMIC) (Raleigh, NC). The outlook of these Credit Ratings (ratings) has been revised to stable from positive.

The ratings reflect FMIC’s balance sheet strength, which AM Best assesses as very strong, as well as its adequate operating performance, limited business profile and appropriate enterprise risk management (ERM).

The ratings upgrade reflects the sustained improvement in FMIC’s balance sheet strength, which is supported by risk-adjusted capitalization at the strongest level, as measured by Best’s Capital Adequacy Ratio (BCAR). The improved assessment is the result of several factors: strong policyholder surplus growth over the past five-year period; solid liquidity metrics; favorable loss reserving trends; and the maintaining of a solid reinsurance program with a manageable retention. Further, surplus growth, coupled with a lower premium base, has led to declining underwriting leverage measures. AM Best expects that FMIC’s operating profitability will continue to increase the company’s surplus base prospectively.

The ratings also reflect FMIC’s adequate operating performance, which is supported by disciplined underwriting practices and a conservative investment strategy. The limited business profile reflects the company’s position as a monoline workers’ compensation writer for the logging and forestry industries, which exposes it to risks associated with the timber industry, such as changes in demand for wood products. AM Best considers the company’s ERM framework and risk management capabilities to be appropriate for its risk profile. FMIC is recognized for its aggressive safety and loss control processes, along with a commitment to long-term stability for its members.

SOURCE: AM Best Upgrades Credit Ratings of Forestry Mutual Insurance Company

Mature and Old-Growth Trees Defining Ambiguity

Ox-y-mo-ron: a figure of speech in which apparently contradictory terms appear in conjunction and are self-contradictory. Such as Responsible Government, in this case – Forest Management.

Washington DC has been described as embodying the best of northern hospitality and southern ingenuity. Not necessarily the epitome of functionality. On “Earth Day” President Biden signed an Executive Order directing the Forest Service and Department of Interior to “define, identify and complete an inventory of old-growth and mature forests on Federal lands.”

It is the “defining” of old-growth and mature timber where the concern should be for the forestry professionals and forest products industries. The variations in regions, species, management practices and numerous other factors create such a level of ambiguity (the quality of being open to more than one interpretation; inexactness) that it is impossible to define a single standard. Hence, defining the undefinable and the oxymoron - defining ambiguity.

Regardless “Old-Growth” has been employed by anti-forest management groups to obstruct forest management to the point of predisposing millions of acres to burn annually. All in the name of protecting the forests. Now throw “Mature Forests” into the equation.

The Climate Forests Coalition, a group of dozens of environmental organizations including Environment America, the National Resource Defense Council, the Center for Biological Diversity, and the Sierra Club prepared a report claiming that logging is the greatest threat to mature and old-growth forests.

The objective of this exercise in defining Old-Growth and Mature Forests is evident: further obstacles to federal forest management. Significant restrictions and limitations already exist regarding Old-Growth forests on federal land. The addition of the new category of “Mature Forests” opens a pandora’s box that would create a new weapon in the arsenal of regular legal challenges to federal forest management efforts.

“Commercial forests are often grown to maturity and then harvested before they reach old-growth status” -Len Montgomery, Environment America Public Lands Director

The irony of this statement is very revealing in that it would advocate that “mature” timber not be harvested in order to allow it to reach “old-growth” status, at which time it cannot be harvested either. This would suggest that timber should be harvested before it reaches maturity, which would be contrary to the position that mature timber is necessary to develop old-growth timber because, under that premise, immature timber must be protected to allow it to become mature timber and later old-growth timber. Hence, under the guise of old growth and mature forest scrutiny, no timber harvest on public lands is the ultimate objective of opponents of professional forest management.

For a government that professes to follow the science, I would suggest that they consider Silviculture. Generally, silviculture is the “science” and art of growing and cultivating forest crops, based on a knowledge of silvics (the study of the life history and general characteristics of forest trees and stands, with particular reference to local/regional factors). The focus of silviculture is the control, establishment, and management of forest stands. The primary benefits of silvicultural practices are; it produces abundant raw materials for the forest products industry; it increases forest cover which is necessary for the conservation of wildlife; and it maintains a perfect water cycle in nature.

The practice of silvicultural-based forest management identifies the process as a stand that is tended, harvested, and re-established. Silviculture is a cycle that requires all aspects of the process to be completed. The harvest age class cycle is based on maturity, which varies from region and species.

The science of silviculture identifies the optimal point, and maturity, at which timber should be harvested. Mature trees are those that have reached their maximum product value, or the point where vigor, health, or growth are declining. Harvesting timber after the point of maturity renders dead, rotten, and diseased forests that are prone to diminish the merchantable value.

Therefore, any consideration defining Mature Forests and Old-Growth Forests, must be based on the science of silviculture and not an environmental agenda of no timber management or harvest. The latter is not scientifically based and is an obvious attempt at creating another false premise to obstruct science-based silviculture forest management practices.

“You must remember that the forest which contributes nothing to the wealth, progress, or safety of the country is of no interest to the government”, President Theodore Roosevelt, America’s “Conservation President”, 1903 speech to the Society of American Foresters, the USDA and the DOI.

This is an exercise in semantics that will accomplish nothing positive toward the forest management goals and objectives of the United States. Implementation of language defining “Mature Forests” will, on the contrary, “create forests which contribute nothing to the wealth, progress or safety of the country, and should be of no interest to the government.”

In conclusion, if the USDA/USFS and DOI were to dangerously attempt to define “Mature Forests”, without basing it on the facts and science, it is merely a pandering exercise in futility that would contribute nothing to the objective of improving forest health and reducing wildfires by forest professionals, but instead would result in another obstruction to federal forest management objectives and healthy forests.

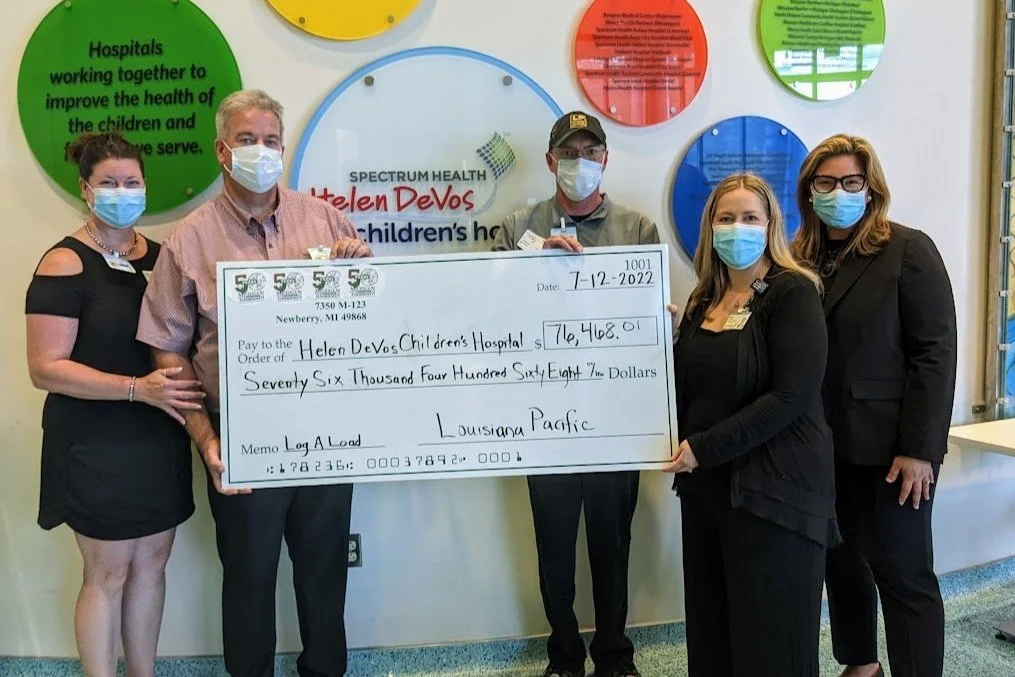

LP-Newberry Log-a-load Event raises over $76,000 for Helen Devos Children’s Hospital!

Travis Kangas, Resource Manager at Louisiana-Pacific (LP) in Newberry, MI, wanted to give back to the local Children’s Miracle Network Hospital, Helen DeVos Children’s Hospital. He started planning a Log A Load event in 2019, but due to COVID, plans were put on hold. Thankfully, Travis was able to start the planning back up, and held a well-attended community Log A Load event in May of 2022.

LP-Newberry donated funds from the 1,704.82 tons of fiber that they harvested. In addition, local trucking partners hauled and delivered the materials to area mills, free of charge, to help ensure that all funds would support CMN Hospitals. The event raised a total of $76,468.01!

Travis also applied for, and received, a Michigan DNR Wheels to Woods Program grant. This grant provided over 100 students and teachers from the Tahquamenon Area School District the opportunity to visit for a mill and timber harvesting tour. Students also used The Ponsse North America Simulator, a close to life simulation of a forest machine environment. This tour was a great event that explained the importance of conservation.

A special thank you to everyone who helped make this event such a success: Arauco, Beacom Enterprises, Biz E Rentals, Cutting Edge Forest Products, David Nayback Trucking, Elenz, Inc., Great Lakes Timber Professional Association, Grossman Forestry Company, Kevin St. Onge, LP Newberry, LP Sagola, MI – Stems, Michigan Association of Timberman, Michigan DNR Wheels to Woods Program, Nathan Hubbard Transport, Northland Harvesting, Ponsee North America, Potlatch Deltic, Tahquamenon Area School District, Travis Kangas.

This gift benefits the Helen DeVos Children’s Hospital Annual Fund, which sustains over 20 programs and services that rely on philanthropic funding to continue. These programs, including the Center for Child Protection, NICU family support, and child and family life, would not be available without their generosity.

Log A Load for Kids is an annual campaign that began in 1988 when loggers and others in the forest products community donated the value of a load of logs to their local CMN Hospital. Today, Log A Load is a leader in CMN Hospitals’ fundraising. This campaign raises more than $2 million annually through golf tournaments, fishing events, dinners, truckloads of log donations and other events.

Shasta College Receives $3.3M For Expansion of Forest Health Programs

REDDING, CA – Shasta College will receive $3.3M as part of a 4-year statewide “Careers in Forestry” partnership to expand forestry and fire-safety training programs throughout Northern California. The Foundation for California Community Colleges (FoundationCCC) is the lead agency for the total grant amount of $21.5 million awarded by the Commerce Department’s Economic Development Administration. The proposal, “California Resilient Careers in Forestry,” will coordinate and expand forestry and fire-safety training programs in northeastern California’s Sierra Nevada and Cascade regions. Shasta College is one of eight regional hub partners working with the FoundationCCC on implementing this grant for the Shasta-Trinity-Tehama region.

Shasta College will leverage the $3.3M award from this grant to expand existing programs in logging, truck driving, and other forest-health-related programs. In addition, the grant money will help to provide additional student support staff, expand the infrastructure needed for the logging apprenticeship program, and improve access for students entering the forest sector, among other initiatives.

On receiving the award news, Superintendent/President Dr. Joe Wyse reflected that “this award is really about scaling up and expanding our existing programs as a result of the State’s investment in the development of our HELO certificate program through CAL FIRE’s Forest Health program. We are so thankful for our industry partners’ advice, resources, and expertise, which have helped position Shasta College as a leader in Forest Health education, training, and support for this critical industry.”

The award announcement spurred industry partners to comment on what this award means and the successful industry partnership with Shasta College.

“Sierra Pacific Industries is proud to support the Statewide Resilient Careers in Forestry Initiative. With the risk of catastrophic wildfires at an all-time high, it is imperative to have a skilled workforce doing the important on-the-groundwork to improve the resiliency of California’s forests. This regional training program is vital to building the workforce that is critically needed to protect the benefits derived from healthy, resilient forests: wildlife habitat, clean air and water, recreation, sustainable forest products, and strong rural economies and communities,” explains Andrea Howell, Corporate Affairs Director at Sierra Pacific Industries.

“I have been personally involved with the college advisory committees throughout the design, development, and implementation of Shasta College’s HELO, CRAFT, and FIRST SEAT programs. Shasta College’s programs are designed to build workforce capacity in our industry and provide opportunity for livable wage jobs for our region,” shares Delbert Gannon, owner of Creekside Logging and Past-President of Sierra Cascade Logging Conference.

To learn more about the Good Jobs Challenge Grant and the “California Resilient Careers in Forestry” proposal, please refer to the FoundationCCC’s press release.

Shasta College is a community college and the only public post-secondary institution in a 10,132 square mile three county area (Shasta, Tehama, and Trinity Counties) in rural far-northern California. Serving over 13,600 students the District has two campuses in Redding, a campus in Tehama, Weaverville and one in Burney in addition to its many online courses and programs. Shasta College offers certificates, Associate Degrees, transfer options, and a completely online Bachelor of Science in Health Information Management. Shasta College has been honored to receive numerous grants for innovative programs that have led to the continued success of the students and communities served. In November 2016 the voters in the communities Shasta College serves voted in a $139 million general obligation bond, Measure disadvantaged communities. The Cap-and-Trade program also creates a financial incentive for industries to invest in clean technologies and develop innovative ways to reduce pollution. California Climate Investments projects include affordable housing, renewable energy, public transportation, zero emission vehicles, environmental restoration, more sustainable agriculture, recycling, and much more. At least 35 percent of these investments are located within and benefiting residents of disadvantaged communities, low-income communities, and low-income households across California. For more information, visit the California Climate Investments website at: www.caclimateinvestments.ca.gov.

John Deere Enhances Knuckleboom Loader Visibility With Cab Upgrades

MOLINE, Ill. (Aug. 8, 2022) — John Deere introduces the latest updates to its Knuckleboom Loader lineup, including visibility enhancements. Aiming to increase operator safety and accuracy, the 2022 models of 437E and 337E Knuckleboom Loaders feature a newly designed front window by removing the external mesh guard and replacing it with a clear, polycarbonate window for uninterrupted view.

“We are always looking for ways to increase operator comfort on the job while keeping a focus on machine safety and design,” said Jarvis de Groot, product marketing manager, Forestry Swing Machines and Knuckleboom Loaders at John Deere. “By removing the external window guard and redesigning the front window on the 437E and 337E Knuckleboom Loader models, we are significantly improving visibility for the operator, making for a safer and more comfortable work environment.”

The 2022 model-year upgrades also feature a new hood profile in the left-rear corner of the machine, which opens up the view behind the machine. The new design partners with the window updates to make for a safer, easier-to-operate machine. By offering enhanced visibility, these models enable the operator to be more precise, maximizing uptime.

In addition to visibility enhancements, the latest models will offer optional satellite-ready radio, improving the operator experience in the cab. A new optional hydraulic vacuum pump can also be added to 2022 model-year machines, minimizing oil loss and spillage during times of hydraulic maintenance and repair.

To learn more about the model-year 2022 knuckleboom loaders, please visit www.JohnDeere.com.

About John Deere

Deere & Company (www.JohnDeere.com) is a global leader in the delivery of agricultural, construction, and forestry equipment. We help our customers push the boundaries of what’s possible in ways that are more productive and sustainable to help life leap forward. Our technology-enabled products including John Deere Autonomous 8R Tractor, See & Spray™, and E-Power Backhoe are just some of the ways we help meet the world’s increasing need for food, shelter, and infrastructure. Deere & Company also provides financial services through John Deere Financial.

Contact: Sam Guinan, Senior Account Executive, imre, SamG@imre.com

Missouri, Going Back to Where It All Began

In 1994, loggers from across the country met in St. Louis, Missouri to discuss forming the American Loggers Council, hoping to provide a national voice for the logging sector of the forest products industry. The meeting was precipitated by the American Forests and Paper Association rolling out the Sustainable Forestry Initiative. A program which was initiated without any input from the logging sector, with disregard for the fact that the burden of implementation and compliance was going to lay primarily upon the loggers.

Spearheaded by Earl St. John, and thirty-three other logging leaders from across the country, the meeting was convened, and over the course of a few days the framework of the American Loggers Council was developed.

That was a gutsy move, especially considering that loggers were expected to be seen and not heard within the industry. Though loggers had previously been silent and fragmented, these leaders stood up and said, “We are going to be heard. We are not going to be dismissed and ignored. We are going to be represented!”

As we’ve recently celebrated Independence Day, it is good to recall that the founders of the American Loggers Council, like the founders of the United States, similarly risked personal ramifications, but still, “pledged to each other our lives, our fortunes and our honor.” In retrospect the risk was worthwhile, as with our nation, so it has been for our organization. The battle belongs to the brave.

Today, the American Logging Council is unquestionably the NATIONAL VOICE OF THE AMERICAN LOGGERS, representing over 30 state and regional associations, nearly 100 Individual Logger Members (ILM), and all major primary industry vendors. You, as a stakeholder in the timber industry, are represented from coast to coast, north to south, from the landing to the halls of Congress.

By: Scott Dane

Where

it all began

2022 ALC Membership Meeting: Branson, Missouri Sept. 22 - 24, 2022 >>

Loggers from Across the Country Converged for a Meeting in Louisiana to Discuss the Future of the Timber Industry

Logging representatives from Minnesota, Wisconsin, Michigan, Ohio, Maine, Idaho, California, Texas, Mississippi, Alabama, Virginia, Missouri, Florida, Georgia, Oregon, South Carolina, Arkansas, Washington, and Louisiana met in historic Natchitoches Louisiana for the American Loggers Council Summer Board of Directors meeting sponsored by International Trucks. The ALC is represented in Louisiana by the Louisiana Loggers Association, the Louisiana Loggers Council, and the Southern Loggers Cooperative. The meeting in Louisiana was precipitated by an invitation from Lt. Governor Billy Nungesser.

Lt. Governor Nungesser along with the help of Larry Roussell and the Louisiana Seafood & Promotion Board, arranged for the donation of seafood from the Louisiana Seafood Association. Also speaking at the dinner was US Congressman Mike Johnson and Louisiana Logger and State Representative, Jack McFarland.

The group toured the largest plywood mill in North America owned by RoyOMartin. RoyOMartin is a family-owned business operating numerous mills and employing 1,200 people. RoyOMartin is not a typical corporate interest. Their focus is on stability, employees, and community. As an example, they provide financial assistance for post-secondary (college) education for all their employees’ and their children; they operate a medical clinic for their employees; they have a pharmacy for their employees. From a stability perspective they are committed to continuous operations even during market cycles and the pandemic. They recognize particularly that logging operations cannot be turned on and off like a light switch. Along with the mill tour, RoyOMartin President & COO, Scott Poole attended the ALC dinner and spoke to the group about the values of the company and their appreciation of the logging industry. In an effort to facilitate more efficient wood deliveries truckers are provided an app which tracks “turnaround time” which averages 23 minutes, and the truckers can also monitor onsite cameras to see truck traffic waiting to come into the mill so that they can minimize their wait time.

The group then toured one of the Southern Loggers Cooperative fuel stations located adjacent to the RoyOMartin mill where logging and trucking members can receive fuel at a discounted rate. A $100 lifetime membership fee to join the Southern Loggers Cooperative is one of the best investments that a logger can make!

RoyOMartin and Walsh Timber Company, co-sponsored Saturday’s lunch for ALC board members at Lasyone’s Meat Pie Restaurant, the women’s plantation tour, and lunch at Cane River Commissary.

The event was a success primarily due to the work and coordination of the ALC Louisiana representatives that arranged much of the logistics and activities. The logging representatives that attended conducted extensive American Loggers Council business, networked, and enjoyed a taste of Louisiana. The ALC is looking forward to welcoming everyone to beautiful Branson, Missouri for the 2022 Annual meeting “Tomorrows Timber Industry”.

Pumpin Pain: Southern Loggin Times I By: David Abbott

This month I determined to find out how rapidly increasing fuel prices are impacting the logging industry, so I reached out to a lot of the people I know. I got enough responses to fill the whole issue, but I only have a page available, so I was forced to cut out a lot of really good observations. Here we go.

“Inflation rate for logging here is anywhere from 38-42%,” says Crad Jaynes, head of the South Carolina Timber Producers Assn. “Quite a few contract haulers have said to hell with it. In my 45 years it is the worst I have seen it.”

South Carolina logger Bob Lussier and Alabama Loggers Council Director Joel Moon have both also been in the industry close to 40 years, and agree with Crad’s assessment. “I’ve never seen anything quite like this,” Moon says, while Lussier notes that he’s seen five economic downturns in four decades, but never before such a rapid escalation of costs.

Carolina Loggers Assn. Executive Director Jonzi Guill says she has not talked to a logger recently who isn't considering downsizing crews or selling equipment. “Our loggers are hurting bad.”

“We seem to feel it much quicker because, unlike on-road truckers who can push added cost on to consumers, we don’t have anyone to push that cost to,” says Toni McAllister, Executive Director of Louisiana Loggers Assn. “We can’t pass our costs on so it feels like it is only our industry suffering, but it is not. It hits us first but it will be all over the U.S.”

“It is devastating to the logging industry,” one Mississippi logger commented anonymously, then summed it all up succinctly: “The margins were already tight but you factor in the diesel prices along with the inflation of every other thing we use in our business, it’s a nightmare. I’m afraid the cost of fuel is gonna put a lot of loggers out of business. We have seen a little help from mills but when you’re getting a 3% bump and you’re seeing 40% inflation…even us ole dumb loggers can figure that math out!”

Within the industry, the big mill companies, with greater assets and deeper pockets, can forestall catastrophe by paying more (although there is only so much they can do). American Loggers Council director Scott Dane predicts that, if mills don't step up, the loggers will run the numbers and be forced to make the hard choice of parking their machines.

Politically, both ALC and President Biden have called for a temporary suspension of federal and state fuel taxes. ALC is also requesting a temporary allowance of untaxed off-road diesel for on-road use, and for log trucks to have access to interstates, to increase fuel efficiency.

Those things could help, some, if they happen. But the only real solution is a market one: demand has to go down, or supply has to go up. Bill Jones, Assistant Director, Southern Loggers Co-op, says things will remain tight until more oil starts being produced in refineries. “It’s not a good situation and I don’t see it getting any better until maybe the fall,” he predicts.

Moon thinks not even then. “The fall is gonna be worse, in my opinion.” His reasoning: fuel prices stay high, but wood products demand declines (consider the Fed’s recent interest rate increase and the effect on housing). Right now maybe mills could pay more; then, maybe they can’t. “Lumber has rolled back a little already and paper usually follows about six months later,” Moon points out. “I think there is a crisis a-coming.”

Supply, Demand

“We are in a challenging situation, with inventories running low at all the terminals across the whole United States,” Jones warns. “We have less than 12 days of inventory in the whole system.”

SLC President/CEO Todd Martin adds, “We have never witnessed the markets move in the way they have moved over the past year, especially since the beginning of this year. It makes it difficult for us to manage and even more difficult for our members to survive. From all indications we are hearing that crude will reach $140 per barrel by the fall.”

Jones goes on to explain, “What has happened on the world market is that the European Union has finally agreed not to buy any more fuel from Russia; they should not buy a drop by the end of the year. There is kind of a weaning off period, but it is putting more pressure on what inventory we have.” He doesn’t expect Saudi Arabia, Venezuela or Iran will release any from their reserves to help.

“If we don’t start producing some pretty soon we will continue to tighten our grip on our inventory and there will be a bidding war for whatever is in those tank farms across the country,” Jones continues. “I don’t expect it to slow down and we might even see some rationing by the middle of the summer. Allocations are tight. Loggers hate the high price but they really don’t like it when they run out.”

Martin reports that SLC has already experienced supply difficulties, especially on the East Coast, and recently in Alabama too.

Despite the high prices, the volume of fuel purchased has not diminished yet. Some SLC stations are posting record days in terms of number of gallons pumped. That’s an upside for members: the co-op has big dividends going out. “The SLC saves our members dollars at the pump, and we also give back,” Martin says. “Each year 100% of the SLC’s net profit is paid back to our members in the form of patronage dividends.”

Jones adds, “We are moving over 200,000 gallons a day and it means something to the logging community that they have a stake in their fuel supply.”

Meanwhile, in June the U.S. Department of Energy announced an allocation of $59 million to accelerate the production of biofuels. “The breakthroughs from this funding will support President Biden’s and DOE’s goals of advancing the use of bioenergy, achieving cost-competitive biofuels, and reaching a net-zero carbon economy by 2050,” a DOE statement reads.

“We have some people in the White House that are dead set on seeing us go to green energy,” Jones points out. “A lot of this is politically charged, I think, to drive us more towards renewable fuels and electric cars, which the grid cannot handle a great influx of.”

Dropping Like Flies

“(We) can’t do what we are doing much longer,” another anonymous logger fears. “I just got through running my P&L for the last five months and am losing $3,500 per week. Not only fuel but everything else costs so much: repairs, parts, tires, etc. Can’t and will not continue to lose money like this.”

It’s not just fuel; general inflation, labor, insurance, equipment, parts, delivery delays, it’s all of it. “Fuel is the main issue but we have had hyper inflation for the last 10 months or so, on every product we buy,” Louisiana’s Josh McAllister says. His wife, Toni, Executive Director of Louisiana Loggers Assn., notes, “We have lost multiple loggers who decided to walk away because of machine breakdowns causing them to be down production for weeks and months before they could receive the parts, and they literally couldn’t afford to sit that long.”

Supply chain delays were already crushing this industry, so in Toni’s estimation, exorbitant fuel prices were just the straw that broke the camel’s back. Now, she says, loggers are dropping like flies. One timber dealer, she reports, recently lost four his nine crews in a week.

“Inflation will kill us slowly; this fuel will kill us this month,” North Carolina logger Brent Roberson warns.

With reports of loggers racking up credit card debt to keep going, Bob Lussier, owner of Great Woods Companies, LLC, Bennettsville, SC, warns, “It is unsustainable. We are losing a few now but in the next 60-90 days we are going to lose a lot,” he fears.

Tim Rodrigues of Rodrigues & Sons Logging in Texas is among those who have found the current situation untenable. He says he has parked or sold most of his equipment rather than continue producing at a loss.

According to Rebecca Pipkin at Mark Pipkin Logging, Arkansas, “We had logged for over 20 years but can’t continue to lose money in this industry. We are no longer logging due to everything going up but our pay.”

Lussier, who serves as President of TEAM Safe Trucking, is already shedding excess equipment and admits he is among those strongly considering the possibility of hanging it all up if something doesn’t change. “I’m not going to keep losing money. When I was younger I had to take money from my savings to keep my business afloat, but I am to the point now I am not going to do that anymore.”

Like Lussier, the McAllisters understand why North Carolina’s Bobby Goodson made his decision a few months to retire early. Toni’s dad, the patriarch of their family business, McManus Timber, is making similar calculations.

This is all no surprise to Richard Schwab at Florida’s M.A. Rigoni. “I think with Bobby going out, he and Lori have inspired a lot of people in that place in their life and career to strongly consider whether they want to re-up in this business climate,” Schwab observes.

“It is a global crisis that is going to be hard for a lot of us to sustain,” Josh McAllister asserts. “We can survive longer than a new company because we have equity built into our business. But we are starting to not break even. So we have to find where the stopping point is; when do we quit using up all our equity? Because that is not a sustainable business model.”

“You don’t want to get to the point of having to dig into retirement savings to make payments,” Moon says. “The company has to support itself.”

“We’ll see what happens sooner than later, but people are folding every day,” Toni adds. “It’s going to put everyone out of business.”

Numbers Game

“The most important thing loggers and truckers need to do is know their numbers, how much more inflation and fuel is costing in the woods and from the landing to the mill,” Scott Dane of American Loggers Council advises. “Once they establish that then it is up to them whether they are satisfied with what the mill is paying or not.”

Lussier agrees. “Loggers need to know the difference between NO and KNOW,” he recommends. “If he knows what his costs are, he can say NO I won’t work for that rate.”

“I think I am seeing in some instances loggers walking away from jobs that would not be profitable to them,” Moon notes.

When logger Brent Roberson was a highway contractor, he worked on a fuel index in which haul rates fluctuated to match fuel costs. “This system is one that is used around the country in the highway market, but unfortunately for us, is not applied in the logging industry,” Roberson says. He suggests a similar index can help loggers and mills calculate adequate logging rates.

Guill says, “The CLA has developed cost calculators to try and help our loggers be able to calculate their cost with the increase in fuel price.” Other groups have been doing the same; for instance, Virginia Loggers Assn. commissioned Dr. Joseph Conrad, Assistant Professor of Forest Operations at the University of Georgia’s Warnell School of Forestry and Natural Resources, to conduct a fuel cost analysis and develop a fuel adjustment formula.

Buck Vandersteen, director of Louisiana Forestry Assn., suggests, “In order to survive we have to ask, do I take a tract that is 80 miles away or decline it for one that is closer but worse timber?”

In a recent letter for ALC, Lussier wrote, “When fuel prices began to rise back in February I really started looking closely at our company's expenses. An individual in another state shared a cost calculator with me that their association uses to help their loggers. We gathered the information necessary for the analysis and ran the numbers. Not only did we want to know what our costs were, but also to be able to show the mills what our costs were. We were very surprised to see how the expense numbers rapidly increased with fuel prices affecting our operating costs.”

Lussier found that his fuel expense for the first six months of the year have increased by 57% over the same period last year, while production is down 30% due to quotas.

“We tried to meet with some mills to show them the findings of the calculator, and to our dismay, some didn't even want to talk about it, and others who have looked at it seem to have no regard.”

Too Little, Too Late

What can be done? “These mills gotta come off it,” Lussier states. “It’s sad that they can all show record profits, but they can’t pass it down to their supply chain that is struggling.”

It is hard, the McAllisters concur, for loggers to see the CEOs of some large, publicly traded companies they work for talking about immeasurable profits and paying billions in dividends to investors, while their suppliers are contemplating having to park or sell their equipment and let go of employees who have been with them for decades, leaving those families without an income. “That is a hard pill for loggers to swallow,” Josh acknowledges.

Toni adds, “We know we are the bottom of their supply chain but they still can’t have that product without us.”

Guill says, “As an association we want to do all that we can to help our loggers succeed, but…until we get some help back from the mills I honestly do not know how long our loggers can maintain.”

Many loggers assert that they can’t make up the difference in production anymore because of quotas. “Inventories are still high at mills, so many loggers are not getting a full week of work,” Vandersteen acknowledges. “Loggers are frustrated with mills; mills are in an awkward position. They have made money, but a lot of it has been reinvested in plant improvements and new plants being built and that is critical for them to stay operating. But a lot of people wonder: could they have done more to help the logging side of the industry?”

In North Carolina, Guill says, “Mills are showing up to the meetings and want to hear what the loggers are saying. The mills have had the upper hand for a long time, and the loggers have worked for years without increases, but this fuel increase is the straw that broke the camel’s back. Some mills have stepped up and offered surcharges, but a lot have not.”

Sources in multiple states report that many mills and timber companies (not all) are in fact paying fuel adjustments, but it usually comes too little, too late. And in some cases, the adjustment came with a cut in delivery price, defeating the purpose.

This industry has changed in 45 years, but in other ways, it hasn’t changed a lick, Crad Jaynes lament. “As long as trucks are going across the scales, they think everything must be lovely…but every load is losing $100 or more,” he says. “It is just so discouraging. I want them to make a profit, but they have been making record profits on the backs of the suppliers and forestland owners.”

Lussier agrees. “It’s the old southern adage: we have wood in the yard, there’s trucks lined up, there ain’t no problem.”

“If you are a logger today and you are relying on a mill to give you what you need without asking for it, you’re not gonna get it,” Schwab counsels. “Loggers have got to stand up and demand it. They’re not volunteering to do anything.”

“Some just want to see how low they can get the price of wood delivered,” Vandersteen points out. “That is a bean counter, somebody who wants a feather in their cap for lowering cost but doesn’t realize the harm they are doing long-term.”

Schwab believes, “The days of trying to push people to do it for less are over. We can’t afford it.”

Like many industry observers and participants, Moon wisely hopes the situation doesn’t deteriorate into loggers and mills fighting each other. That, he believes, would ultimately prove counterproductive for all involved. “Loggers and mills are partners,” he asserts. “We’re all in this together.”

Politics

Some express an exasperated hope that they can just hold on till the end of 2024, when they hope to see an administration change. But even after the next election, Lussier points out, it will take a long time to fix what seems to have been broken.

Moreover, while many in the industry lean to the conservative end of the political spectrum, that doesn’t mean they blindly trust Republican politicians to do the right thing. Some suggest that, though they may view Democrats as clueless or incompetent, they fear that Republicans, in some cases, may actually want to keep things bad, to better their chances of winning in upcoming elections.

“I can’t be mad at Biden,” Lussier says. “He is doing exactly what he promised to do. But I am mad at Republicans because even though they are not in the majority they are just sitting back and letting it happen. We don’t need to drain the swamp; we need to flush the toilet.”

Lussier continues, “To blame just the Democrats is not fair. What are the Republicans doing about this? This party division has got to stop. We are ALL Americans.”

Source: David Abbott (Southern Loggin’ Times)

ALC to be the National Sponsor of Log-A-Load for Kids

The American timber industry has not experienced a more challenging and difficult period. The current economic and inflationary period is having a more detrimental impact on American loggers and truckers than the housing collapse, “Great Recession” and the COVID pandemic.

Multi-generational businesses are closing, companies are ceasing operations, liquidating, and going into different occupations. It is aggravating and frustrating when owners have invested blood, sweat and tears into building their business only to do the math and see that the numbers don’t add up to staying in business.

Sometimes we can’t see the forest for the trees. Rightfully, the challenges to the industry need to be focused on, but when we step back and see the “big picture”, our challenges and concerns come into perspective. Nothing guides our attention to what really matters more than seeing the most vulnerable suffering health challenges. When a child is sick or injured a family’s world is turned upside down.

Heaven forbid that anyone has a need for their children to go to the hospital, but we thank God that the Children’s Miracle Network Hospitals are available when there is a need.

That is why in 1988 Larry and Carol Connelly, a logging family from South Carolina played a key role in establishing the Log-A-Load for Kids campaign through the Children’s Miracle Network Hospitals Fundraising Telethon. The basic concept was for loggers and wood-supplying mills to donate the value of a load of logs to a local Children’s Miracle Network Hospital. That has evolved into other fundraising events to support the Log-A-Load program, with 100% of the donations going directly to help children. This ensures that families can receive the needed medical services for their children without any out-of-pocket expense.

Since that time, the Log-A-Load for Kids program has spread to over 30 states and raised more than $46 million for 70+ member hospitals. Today, Log-A-Load for Kids is a leader in the Children’s Miracle Network Hospitals’ fundraising with more than $2 million annually through golf tournaments, fishing events, clay shoots, dinners, auctions, truckloads of log donations, and other events.

Florida - Donated over $2 million

Mississippi -Nearly $2 million

Arkansas Over $9 million

Maine - Nearly $2 million

Mountain Loggers Group - $2 million to Log-A-Load for Kids

Many of the state logging association members of the American Loggers Council sponsor Log-A-Load for Kids events. That is why the American Loggers Council has accepted the opportunity to support the Log-A-Load for Kids program nationally by promoting it and supporting the state efforts. As a demonstration of support, the American Loggers Council has donated six Loggers Limited Edition Henry Rifles to state association auctions and raffles. These donations have contributed $35,000 to the state efforts.

For the American Loggers Council our purpose is to facilitate, encourage and enable the members – the state logging associations in all their endeavors. The American Loggers Council’s role in the Log-A-Load for Kids program nationally is focused on supporting the leaders of the program, the state logging associations, and contributing to their efforts as they provide for the children in need.

Business and life are about more than the bottom line, it’s about helping when help is needed, it’s about giving back.

Because needs don’t only occur when it is convenient or when we are prosperous, we are called upon to support one another in good times and in bad times. Even during these economically challenging times, loggers have not lost perspective and have continued to donate generously and increasingly to the Log-A-Load for Kids program.

For more info visit: https://www.amloggers.com/log-a-load-for-kids