LATEST NEWS

PLC of Maine Raises Record $262,403 for Log-a-Load for Kids in 2022

PLC Executive Director Dana Doran, at right, presents a check for $262,403 to Kelly Pearson, at left, Director of the Children’s Miracle Network Hospital program and Corporate Engagement at Northern Light Health; and Kate Richardson, center, Children’s Miracle Network Senior Philanthropy Manager for Barbara Bush Children’s Hospital.

Funds raised for Children’s Miracle Network Hospitals in Maine

AUGUSTA, MAINE – The Professional Logging Contractors (PLC) of Maine raised a record $262,403 for Children’s Miracle Network Hospitals in Maine in 2022 through its annual Log A Load for Maine Kids fundraising efforts.

The total shattered the previous record set in 2021 of $205,000, with the PLC’s two Log A Load golf tournaments and the Log A Load live auction at the PLC’s annual membership meeting each hitting new highs in 2022.

“It is incredibly inspiring that despite the many challenges facing Maine’s logging industry, PLC’s Members, Supporting Members, friends, and families have rallied to once again raise a record amount for Children’s Miracle Network hospitals,” Dana Doran, Executive Director of the PLC, said. “No matter what obstacles they encounter in their own businesses and lives, they always reach deep for the kids and their families.”

On Friday, Doran presented a check for the funds to representatives from Northern Light/Eastern Maine Medical Center in Bangor and The Barbara Bush Children’s Hospital at Maine Medical Center in Portland. The check was presented at the PLC’s office in Augusta.

Those accepting the check on behalf of the hospitals were Kelly Pearson, Director of the Children’s Miracle Network Hospital program and Corporate Engagement at Northern Light Health, and Kate Richardson, Children’s Miracle Network Senior Philanthropy Manager for Barbara Bush Children’s Hospital (BBCH).

“The logging community continues to amaze us. We are touched by their generosity and compassion. The dollars raised make a real difference in the care our doctors and nurses provide to local kids. Northern Light Eastern Maine Medical Center has used the funds to support programs and services, and purchase equipment like a new ambulance and an ultrasound machine, as well as comfort items like new stuffed animals. On behalf of our patients, their families, and the team that cares for them, thank you,” Pearson said.

“It’s difficult to express the lifesaving impact that this industry is having on our local children’s hospitals. It’s evident that there is a deep-rooted commitment among members of the logging industry to support their community and help their neighbors – and that’s exactly what they’re doing by ensuring that our kids have access to the very best care, right here in Maine. I’m constantly amazed and deeply grateful for the tireless efforts and remarkable generosity of Maine’s logging community,” Richardson said.

The PLC raises the majority of Log A Load funds during an auction at its annual membership meeting in the spring and at golf tournaments in Lovell and Lincoln in August and September. Some additional funds are raised through the sale of items including holiday ornaments and through end of year donations.

The PLC’s Log A Load efforts have now raised more than $1.925 million since 1995. In addition to setting records at both golf tournaments this year, the PLC Annual Meeting Log a Load for Maine Kids Auction also set a record, raising $144,399.

The PLC and the Northern Light Health Foundation (formerly Eastern Maine Health Systems Foundation) have partnered in the Log A Load fund-raising effort since 1996. Donations have gone to support research and training, purchase equipment, and pay for uncompensated care, all in support of the mission to save and improve the lives of as many children in Maine as possible. Eastern Maine Medical Center in Bangor is a Children’s Miracle Network Hospital and includes a Neonatal Intensive Care Unit that has received support for years from the PLC’s Log A Load efforts.

The PLC partners with The Barbara Bush Children’s Hospital at Maine Medical Center in Portland for the southern tournament.

The South Carolina Forestry Association started the Log A Load for Kids program in 1988. Originally, the concept was for loggers, wood-supplying businesses, and other industry supporters in various states including Maine to donate the value of a load of logs to their local Children’s Miracle Network Hospitals.

Nationally, Log A Load for Kids is a leader in CMN Hospitals’ fundraising, raising more than $2 million annually through golf tournaments, fishing events, dinners, truckloads of log donations and other events.

For more information, please visit www.logaload.org.

Maine’s loggers are a vital part of the state’s forest products sector, which is worth an estimated $7.7 billion annually. Logging contributed an estimated $619 million to the state economy in 2017.

Founded in 1995 with a handful of members who were concerned about the future of the industry, the PLC has grown steadily to become a statewide trade association which provides independent logging contractors a voice in the rapidly changing forest products industry. Board membership consists of only loggers, making it an organization that is run by loggers on behalf of loggers. PLC members are responsible for cutting 75 percent of the timber that is harvested from Maine’s forests annually.

Learn more about the PLC at www.maineloggers.com.

CONTACT: Dana Doran, Executive Director, PLC, Phone: (207) 441-3621

Ponsse Expands to South, Opens Location in Florida

Ponsse North America Inc. has expanded its operations to Midway, Florida, which is near Tallahassee. The company said the move was in response to growing demand for cut-to-length wood and an increase in machine sales in the South.

“Forestry is our focus and all we do,” said Pekka Ruuskanen, president and CEO of Ponsse North America. “We are extremely excited about our expansion to the South because of the number of mill investments with new facilities opening, reopening of shut down mills, and capacity increases.”

“It is time for cut-to-length to be more dominant in the South like it is currently in the northern part of the USA,” he added.

Ponsse’s new Florida facility will offer sales, parts, and service – the same as all other Ponsse locations. Tyler Amundson is heading the new location.

“We want to provide all of our customers with the best machines in the world, exceptional service, and the best parts availability in the industry,” said Ruuskanen.

Ponsse North America is a subsidiary of Finland-based Ponsse and was established in 1995. Its headquarters is in Rhinelander, Wisconsin.

In addition to its new Florida location, Ponsse has branches in Wisconsin, Michigan, Minnesota, and Oregon. It also has full-line dealers and service dealers in various locations throughout the country.

Ponsse is one of the world’s largest manufacturers of rubber tire cut-to-length forest machines. The family-owned company was founded in 1970.

Ponsse machines cover all size categories, from first thinning and harvesting forest energy to heavy-duty regeneration felling, as well as all types of logging sites, from soft soil to steep slopes.

To contact the Ponsse facility in Midway, Florida, call (850) 513-3324. For more information about Ponsse machines, visit www.ponsse.com.

Building Demand Boosting Utilization: Wood Bioenergy Hatton-Brown Publishers

The news that Strategic Biofuels in Louisiana is working with the Forest Service and other groups on biomass standards is big. Developing a Renewable Fuel Standard (RFS) system to make it easier to incorporate forestry feedstock into biomass and green energy initiatives and projects by ensuring raw materials meet sustainability standards is going to make utilization of woody biomass more attractive—and that’s good for the wood bioenergy industry.

Having such a system is yet another tool to aid in the increased utilization of wood as a sustainable energy source. Strategic Biofuels is taking the lead in developing an auditable system to track feedstock qualification, source-origin and chain of custody data to support its Louisiana Green Fuels project that will use woody biomass to produce renewable diesel and naphtha.

While the Louisiana facility is expected to break new ground with a negative carbon footprint and also incorporate well-based carbon sequestration technology, the use of woody biomass as a biofuel feedstock is an encouraging sign.

The EPA is required under the Clean Air Act to set RFS volume requirements each year. There are four renewable fuel standards—conventional renewable fuel, advanced biofuel, cellulosic biofuel, and biomass-based diesel.

Traditionally, biofuel has been the province of big agriculture: “Conventional renewable fuel” is mostly corn ethanol; “advanced biofuel” uses mostly non-food crop ag residues and industrial waste as feedstock; “cellulosic biofuel” uses mostly corn stover and similar products; and “biomass-based diesel” has seen soybean oil as its biggest feedstock.

Julie Tucker, National Wood Innovations Program Manager of Bioenergy, Biofuels, and Bioproducts, U.S. Forest Service, notes that “Historically, forest residuals have been a disposal challenge. The Renewable Fuel Standard helps change that by giving the renewable energy sector a financial incentive to convert these unwanted forest residuals to high-value biofuels and renewable electricity.”

Tucker adds that EPA must ensure that forest residuals receiving credit under the RFS are qualifying feedstock: “We also want them to be sustainably sourced. This initiative with Strategic Biofuels is an exciting opportunity to do that.”

With large amounts of forest residue volumes available in timber-rich regions of the U.S., it’s important to see timber-based biomass standards set and met. This is especially true in areas where forest health issues and projects create large amounts of biomass available for utilization.

While the development group is being led by the Forest Service and Strategic Biofuels and the full team is still being assembled, members will include representatives from the National Assn. of State Foresters and the American Loggers Council as well as groups representing industrial and non-industrial landowners, tribal interests and others.

It’s critical to have a wide range of stakeholders involved, including wood bioenergy interests, to help develop such a system that has national implications for increased biomass utilization—and help ensure the wood bioenergy industry’s concerns are heard as biomass standards and tracking systems are established.

SOURCE: WOOD BIOENERGY MAGAZINE HATTON-BROWN PUBLISHERS

Urban Society vs Rural Cultural Traditions: The Real Crisis in the Forest

For many decades, urban society and its “illusion of preservation” has continued to obstruct and suppress our rural communities and their use of the land and natural resources. We are seeing the elimination of our cultural heritage in our time.

Since 1985, Bob Williams has worked as a consulting forester in New Jersey working with both private and public landowners.

In southern New Jersey by government legislation, 1.2 million acres of the landscape has been reserved and protected in what is designated as the Pinelands National Reserve. This reserve includes all aspects of the land ownership both public and private.

Two of the primary reasons for designating the Pine Barrens for protection was to perpetuate and sustain the unique ecological natural heritage and the indigenous local cultural heritage.

We understand the essential need to sustain and conserve the ecological integrity of the land and the natural systems it supports.

Our urban policymakers understand little about the need to conserve our cultural heritage which are both tangible and intangible heritage assets that the local people inherited from past generations.

Whether intended or not, this policy of an environmental priority approach has all but eliminated one aspect of our cultural heritage which is forestry. The region had a tradition of using the forest by local people to provide a living for themselves and the local traditional use of wood products produced on the land locally.

Over the decades, the importance of sustaining our historical cultural human resources has never been given any serious consideration or discussion.

In the early eighties, the government stressed the need to sustain and conserve the cultural heritage of the Pine Barrens. This concern was so important that social contractors were hired to interview and record local pine barren residents to have them explain what specific things they did to sustain themselves and their desire to keep their sense of “place” in the woods.

Yet when I bring this subject up, I’m asked what cultural heritage has to do with forestry regulations? My answer: everything.

Interviews with local folks included many cedar landowners, woodcutters, and sawyers. They all owned their land, cut their trees, and had their sawmills to sell culturally linked forest products to boat builders, clammers, fishermen and historic home restorers to mention a few uses. As this effort to document and develop policy to sustain the cultural and natural history of the region continued, it was made clear how important the role these woodsmen played in sustaining the unique character and ecology of this region. The forest use played a key major role in the creation of the very environment of the Pine Barrens.

It was so important that by 1987 the New Jersey State Museum, the State Council on Arts, and the State Historical Commission opened the largest exhibit ever mounted of the museum devoted to four men who were fully devoted to the traditions and the environment of the Pine Barrens. Yet the future for these traditions remained a concern.

Initial forestry practice rules and regulations subjected forestry efforts to onerous land planning rules similar to housing development. By the early 1990’s many families had simply gone out of business while a few tried to supply their mills with imported wood from Canada or New England. The acquisition of the large, forested parcels by federal, state, county, and local governments, as well as the many land preservation, trusts all of whom do not support an active harvest of wood simply starved the local mills of their needed wood resource and the decline continues today.

Our southern New Jersey woodcutter culture is almost gone. At the beginning of the creation of the Pinelands Reserve, the state documented more than 50 sawmills and operations across the Pine Barrens. I have watched as our forestry infrastructure with its 300-year history simply fade away falling to the “illusion of preservation”.

The original planners for the Reserve had it right – there was to be a balance between the people – use of the forest and the unique biodiversity that resulted from three hundred years of their activities. Yet I see little hope for any of the few remaining sawmills to survive. How are things looking your region of the county?

WRITTEN BY: Bob Williams, Pine Creek Forestry

Thanksgiving Perspective

It is a matter of perspective, we can either look at the glass as half full or half empty. Either way it is the same glass, it just depends upon how we choose to look at it. If you are thirsty, you can be grateful for half a glass of water, or you can be resentful that it wasn’t a full glass of water. That is how life, particularly in the woods, can be. Loggers and truckers tend to be “glass half full” optimists.

There are few “easy” days in the woods or hauling timber. The challenges are daily, sometimes hourly. But if you have been in the timber industry, it is a way of life. Honestly, that may be what drives loggers and truckers to do what they do. It is a life most others cannot or will not live. As such you have overcome insurmountable challenges and threats; you have replenished your glass and never let it be empty.

As we prepare for the Thanksgiving celebration, remember that it dates back to colonial times and the harvest feast. When settlers and Native Americans came together and shared a meal. The New England colonists regularly celebrated “days of prayer thanking God for blessings”. Later, a national Thanksgiving Day was officially designated by President Lincoln to promote unity during the Civil War.

If there has been a time since the Civil War that the United States needed unity, it is today. Despite all of the division, vitriol, and conflict today’s United States can take a lesson from 400 years ago, when two vastly different cultures, who were at times warring factions, sat together, ate together, and gave thanks TOGETHER. This historic demonstration of unity is an example of what America needs today and a reminder that we still have a lot to be thankful for this Thanksgiving Day.

The timber industry is comprised of competing factions, including loggers vying for the same timber tract, mill volume, laborers, and trucking capacity. Yet most come together to work towards a common mutual benefit of a sustainable timber industry through their membership in state and national organizations. They recognize that through unity a greater good can be achieved. Perhaps there should be more loggers and truckers running the country. Men and women who face the daily challenges of harvesting timber and transporting it, who can solve problems, who are focused on the common good, who build instead of destroying, who focus on the good, not the bad, and who are thankful for the blessings they have received.

Whether we choose to look at all of the blessings we enjoy today, or if we choose to look at the challenges, differences, threats, and disagreements that divide us, is up to each of us.

Gratitude and Attitude are not Challenges; they are Choices.

Thanksgiving is about unity, and the unity of our country, but more importantly, Thanksgiving is about giving thanks to the source of our blessings – God.

Ephesians 6:12 – For we wrestle not against flesh and blood, but against principalities, against powers, against the rulers of the darkness of the world, against spiritual wickedness in high places.

Charles Spurgeon said, “The Lord’s mercy often rides to the door of our heart upon the black horse of affliction.”

During the Thanksgiving holiday, be sure to have the right perspective, count your blessings – your health, your family, your business, and give thanks to the One from whom all blessings flow. Even in the challenges be thankful.

Be Thankful for Every New Challenge. It will Build Strength, Wisdom, and Character.

With that perspective, in times of blessings and in times of challenges, we can be thankful and give thanks.

“The secret of happiness is to count your blessings while others are adding up their troubles.” –William Penn (American Colonialist)

Get In the Wheelbarrow!

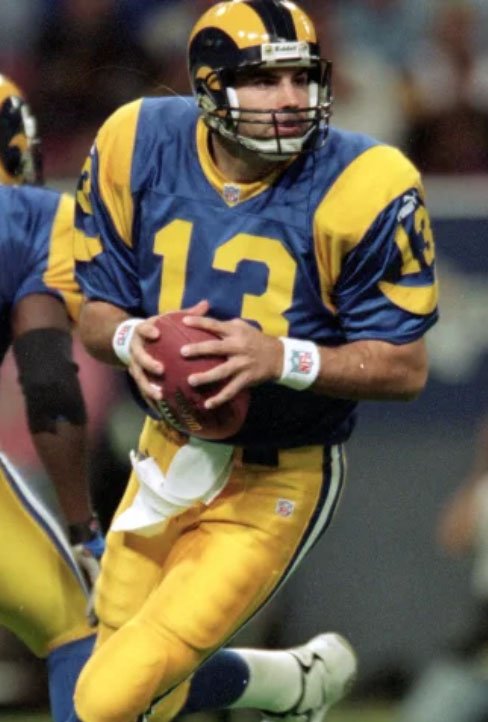

Superbowl Champion Quarterback Kurt Warner sent a letter to the American Loggers Council that was shared at the Annual Conference. In it, Kurt conveys a story regarding a symbolic reminder to the 1999 Superbowl Champion, St. Louis Rams football team during their practices. Their coach Dick Vermeil had a blue wheelbarrow on the sidelines. It was a visual motivational reminder to inspire the team and was based on the following story:

There once was a man who traveled from town to town performing a tightrope act. In one town he proclaimed that he would walk on a rope spanning a nearby wide river canyon. He boasted he would do it pushing a wheelbarrow.

Townsfolk didn’t believe him, so he practiced flawlessly just five feet off of the ground on a rope tied between a pair of trees. After seeing the tightrope walker practice one farmer said he believed the man could cross the river canyon. He even bet $10 to prove his faith in the man’s skills.

The man asked the farmer if he really had faith that he could do it? The farmer said, “I sure do.” The tightrope walker said, “Okay, get in the wheelbarrow!”

The moral of the story is some believers stand on the sidelines and believers that get in the wheelbarrow. Kurt’s letter closes with:

“Success in any field begins with faith. Faith in yourself. Faith in your teammates. Faith in coaches. And in my case faith in God. The championship teams that I played with had faith. We climbed in the wheelbarrow together. So – Keep the Faith”

Kurt Warner was an American underdog who got his chance to play for the St. Louis Rams in 1999 after having been passed over by other teams. The American Loggers Council got its chance in St. Louis Missouri in 1994 when the “team” was formed by a bunch of American underdogs who had faith – faith in themselves, faith in each other and faith in God. They got in the wheelbarrow together and over the past 28 years crossed many canyons while building a championship team. They didn’t stand on the sidelines, they got in the game. They took the hits, but they carried the ball and scored! The American Loggers Council is a championship team!

Kurt also autographed a poster titled Legacy which said:

“Legacy – Live a Life that Inspires Others to Dream Bigger, Try Harder, Do Better and Accomplish the Unexpected.”

Those that came together to form the American Loggers Council in Missouri in 1994 have left a legacy because they inspired others to dream bigger, try harder, do better and accomplish the unexpected. They had faith and got into the wheelbarrow. Today’s American Loggers Council is their legacy. Some of them were in Branson and were recognized. Representing the first President, Earl St. Johns was his grandson, Jordan St. Johns, and his great-grandson. Also present and recognized were inaugural representatives Jim Carey (MI) and Eric Mayranen (MN) and Charles Johns (FL). Representing Marvin Zuber (OR) was his son, Bruce Zuber, Western Regional Representative of the American Loggers Council.

The legacy of the American logger has been recognized. It was announced at the conference that a Resolution was introduced in the U.S. Senate to designate October 12th as National Loggers Day. This resolution honors the American Logger for their role in building America; producing products for Americans from the renewable timber harvested; creating jobs; and forest management which results in healthy forests that provide recreational opportunities, animal habitat, clean water, carbon sequestration and reduction of wildfires. The designation of this National Loggers Day was achieved because (team) members of the American Loggers Council worked together to garner this overdue national recognition. So loggers, on October 12th, take a moment to proudly reflect on what you do, on what your fathers and grandfathers did, and how it contributes to building America every day. Without loggers, America would not be the great country it is today. You are an American legacy.

Kurt Warner and his wife Brenda run the First Things First foundation which is dedicated to impacting lives in a lasting way by promoting Christian values, sharing experiences, and providing opportunities to encourage everyone that all things are possible when people seek to put “first things first”. When Kevin Smith, American Loggers Council Director of Communications and Marketing, contacted the First Things First Foundation and explained to them that the American Loggers Council is the national sponsor of the Log-A-Load For Kids program and that we would be holding a fundraising auction at the conference, Kurt responded with the letter and autographed Legacy poster.

With great success comes great responsibility. Kurt Warner accepts this and so does the American Loggers Council. The ALC has been blessed with success, and, like Kurt, appreciates the responsibility to help others and impact their lives in a positive way. The Log A Load For Kids auction raised over $56,000! In addition, an impromptu auction to support a logger dealing with cancer was conducted. The two items (autographed Duck Dynasty duck calls and Stihl chainsaw) that were donated were auctioned – donated back – then reauctioned - numerous times, raising a total of $38,000.

The outpouring of support and generosity demonstrated by loggers from across the country for children in Missouri and a logger in Louisiana was a testimony of the character of the logging community and family.

Two-hundred and fifty timber industry representatives came to Branson Missouri from across the country to represent the American logging industry. They met to discuss and explore “Tomorrow’s Timber Industry”. To share ideas and thoughts, much like loggers did 28 years prior when they formed the American Loggers Council, to ensure that there is a viable future for the next generation. They came together to be responsible corporate stewards and support their communities. They came together to be part of a team, a winning team, and to make a difference – and what a difference they made!

The American Loggers Council now represents loggers in 38 states. If you are reading this, and you are not a member of your state logging association or the American Loggers Council, don’t be a believer that stands on the sidelines, be a believer that gets in the wheelbarrow. Be a part of the team!

Loggers Celebrate Resolution Designating October 12th as National Loggers Day

The American Loggers Council announces the introduction of a Senate Resolution, House Resolution of Support, and Letter of Recognition from President Biden designating October 12th as “National Loggers Day”.

The American Loggers Council announces the introduction of a Senate Resolution, House Resolution of Support, and Letter of Recognition from President Biden designating October 12th as “National Loggers Day”.

Loggers were a part of carving out a new life in America 400 years ago and they continue to build America every day. Loggers today carry on the proud tradition that has been a part of the American fabric since the beginning and will continue to be in the future. The proud timber industry heritage depicted by the iconic Paul Bunyan lives on in today’s loggers. They are an American legacy.

“Our forest products industry has supported good-paying jobs, driven local economies, strengthened rural communities, and protected our natural environment. I come from a six-generation forest-products family and know of no other enterprise that requires more faith in the future and respect for the past,” said Senator Collins. “I am proud to join Senator Baldwin in honoring the skilled and resilient loggers in Maine and across the country. I have strongly supported these hardworking men and women by advocating for workforce development programs and securing financial assistance during the pandemic, and I look forward to continuing to be a strong partner on issues to protect this resilient industry and its talented employees.”

“I’m proud to lead this bipartisan effort with Senator Collins to spotlight the importance of logging businesses and workers who keep our forests healthy and support our Made in America forest products supply chain,” said Senator Baldwin. “Wisconsin’s logging economy provides good-paying jobs and revenue for rural communities and the National Park System. Healthy forest management also provides public recreational opportunities that make the Wisconsin way of life a national treasure. With this bipartisan Senate Resolution, we are showing our commitment to the loggers who work hard to advance what has been a cultural tradition in the United States for centuries.”

“The significance of this proclamation for loggers across the United States cannot be overstated,” Dana Doran, Executive Director of the Professional Logging Contractors of Maine, said. “At no prior time in our nation’s history have loggers been recognized for their selfless and heroic efforts by our nation’s government, and we especially want to thank U.S. Senator Susan Collins for leading the effort to honor their contribution to our nation’s economy on behalf of the hard-working small family businesses in the industry. Loggers work hard day in and day out to supply every American with products that they need to live safe and productive lives. It’s important to not only honor this heritage industry but also to be sure that every American recognizes the importance of their contribution now and in the future.”

Loggers supply the renewable resources that the forest products industry (paper, lumber, biomass, etc.) requires to produce the products that people need, use, and depend on. That is why they were deemed essential and continued working through the pandemic.

American forests are healthy and sustainable due to the services that loggers provide to the public and private forest managers which allows them to meet their sustainable forest management objectives.

The American logger contributes to improving rural communities, forest health, animal habitat, wildfire mitigation, carbon sequestration, and renewable energy development. Without loggers, these public economic and environmental benefits would not be possible.

The American Loggers Council appreciates the Congressional and Presidential recognition of the American Logger and the contribution that they have made for generations in building America.

Congressman Good (VA) plans to introduce the Resolution of Support this week and it is anticipated to pass and officially recognize October 12th as National Loggers Day.

John Deere Introduces New FR27 Disc Saw Felling Head

MOLINE, Ill. (Sept. 29, 2022) — John Deere is excited to announce its newest forestry attachment offering with the FR27 Disc Saw Felling Head. Now standard on the John Deere 953M and 959M feller buncher models, and available as an upgrade on the on the 853M, 859M and 903M feller bunchers, this felling head attachment has a larger cut capacity compared to previous felling head models. Building upon the success of the FR24B, John Deere has successfully designed the durable FR27 as a solution aimed to increase productivity on the job.

“We are always looking for ways to enhance operator efficiency and machine capacity. By introducing a larger felling head solution to our line-up with the FR27, we are providing our customers with a larger, more durable attachment to help increase their bottom-line,” said Jim O'Halloran, global product marketing manager, tracked feller bunchers and harvesters & disc saw felling heads, John Deere. “The newly designed FR27 enables loggers of all experience levels to tackle even the most ambitious jobs with confidence knowing their machines are built to endure larger timber and excel in a variety of forestry applications.”

The FR27 Disc Saw Felling Head is designed to take on a variety of timber applications, from large single stem cutting to mid-sized accumulation, and boasts an all-new design and overall rebranding from previous John Deere felling head models. In addition, this robust, high rotation felling head features excellent cut and accumulation capacity, offering top-of-the-line productivity compared to previous models. The FR27 features an impressive cutting capacity of up to 27.2 in. and an accumulation capacity of up to 7.5 ft, improving capability in the woods.

Building upon the success of the field proven FR24B, the FR27 features an updated frame and wrist design, which includes a tall horn, long harvesting arms and continuous hose routings that promote easy machine clean-out. The hardened saw housing wear plates are now standard and offer improved saw housing wear resistance.

Additionally, the FR27 offers bolt-on saw housing for improved serviceability, with three separate saw housing sections with integrated skis getting you back on the job sooner. The incorporated large side chip exhaust chute minimizes build up and plugging, keeping your machine up and running. The side chip exhaust chute also includes a cover that can be added or removed depending on application.

Starting now, the FR27 are available for purchase on the 800 and 900 M-Series Feller Bunchers models. To learn more about the FR27 Disc Saw Felling Head or the full line-up of John Deere forestry solutions, contact an authorized John Deere dealer or visit www.JohnDeere.com/.

About John Deere

Deere & Company (www.JohnDeere.com) is a global leader in the delivery of agricultural, construction, and forestry equipment. We help our customers push the boundaries of what’s possible in ways that are more productive and sustainable to help life leap forward. Our technology-enabled products including John Deere Autonomous 8R Tractor, See & Spray™, and E-Power Backhoe are just some of the ways we help meet the world's increasing need for food, shelter, and infrastructure. Deere & Company also provides financial services through John Deere Financial.

For more information on Deere & Company, visit us at www.deere.com/en/news/.

Contact: Sam Guinan, Senior Account Executive, imre, samg@imre.com

NATIONAL LOGGERS DAY: Collins, Baldwin, Risch, Cassidy, King, and Daines Introduce Bipartisan Resolution Recognizing National Loggers Day

Senator Susan Collins (R-ME), Tammy Baldwin (D-WI), James Risch (R-ID), Bill Cassidy (R-LA), Angus King (I-ME), and Steven Daines (R-MT) introduced a bipartisan resolution recognizing October 12th, 2022 as National Loggers Day. The Senate resolution highlights the many contributions and economic benefits of the logging industry in the United States.

“I’m proud to lead this bipartisan effort with Senator Collins to spotlight the importance of logging businesses and workers who keep our forests healthy and support our Made in America forest products supply chain,” said Senator Baldwin. “Wisconsin’s logging economy provides good-paying jobs and revenue for rural communities and the National Park System. Healthy forest management also provides public recreational opportunities that make the Wisconsin way of life a national treasure. With this bipartisan Senate Resolution, we are showing our commitment to the loggers who work hard to advance what has been a cultural tradition in the United States for centuries.”

“Throughout Maine’s history, our forest products industry has supported good-paying jobs, driven local economies, strengthened rural communities, and protected our natural environment. I come from a six-generation forest-products family and know of no other enterprise that requires more faith in the future and respect for the past,” said Senator Collins. “I am proud to join Senator Baldwin in honoring the skilled and resilient loggers in Maine and across the country. I have strongly supported these hardworking men and women by advocating for workforce development programs and securing financial assistance during the pandemic, and I look forward to continuing to be a strong partner on issues to protect this resilient industry and its talented employees.”

This resolution is supported by the American Loggers Council.

Designating October 12, 2022 as “National Loggers Day”.

Whereas, the logging industry has served as an economic driver and cultural tradition in the United States for centuries;

Whereas, the logging industry creates rural jobs and provides revenue for local and state governments, and ;

Whereas, loggers provide renewable material for products used by Americans every day;

Whereas, loggers are the first link in the $300 billion domestic forest products supply chain;

Whereas, loggers are the means by which healthy forest management plans are accomplished;

Whereas, logging provides for healthy forests that maintain our vital animal habitats;

Whereas, logging provides for healthy forests which protect our watersheds;

Whereas, logging provides for healthy forests which sequester carbon;

Whereas, logging provides for healthy forests which provide public recreational opportunities;

Whereas, logging provides for healthy forests which reduce loss of life and property from wildfires;

Whereas, logging provides for healthy forests through regeneration, including planting 2.5 billion trees annually.

Inflation’s Impact on Contract Logging

With sincere apologies to my high school English teacher, Mrs. Johnson (she tried her very best), and knowing that article composition is well outside of my limited wheelhouse, allow me to attempt to convey what effects inflation has had on a “typical” contract logging business.

In this article, I will trade back and forth between two hats: a logger’s viewpoint with forty years of hard knocks experience; and the current Board Chairman of the Carolina Loggers’ Association, offering how the CLA is working to help with the situation.

Arcola Logging Company/Arcola Timber Transport is typical when it comes to logging contractors in the southeastern United States. Partnered with another VA logger, we are fully independent, buying 100% of our own stumpage, and work primarily in northeastern North Carolina and southeastern Virginia. Arcola runs two crews – one concentrating on clearcuts and chipping, the other smaller crew with thinning capability. We also do 100% of our own trucking. We maintain ten trucks, running eight full time.

We face the same common issues we all hear about: the dwindling availability of qualified employees (both in the woods and truck drivers), stumpage availability and production markets, and, of course, cost inflation which is the focus of this article. One important point I need to stress: when talking about logging costs, the word “typical” does not apply. There are so many variables in each operation that we all operate vastly differently, and generalizations should be avoided when working with these figures. One of the few perks I claim of being in my sixties is that I do know it all, so each day, I exercise my vast knowledge and come up with the day’s “plan.” By 6 am, with employee issues, truck/equipment issues, quotas and markets, the weather, someone’s Mama’s stubbed toe, and quite a few other possibilities, I am shown how very little I actually do know. So many variables, and they all need to be considered when discussing logging costs because they come into play daily.

My 23-year-old son, who is out here with me now, likes to remind me that I already have one foot in the grave, with the other possibly joining it at any time. I do remember the inflation of the 1970s being 7 to 12 % for several consecutive years and loan interest rates of 15 to 20% were the norm. Wood producers at that time were not as capital-intensive businesses as we are today, and most barely survived the 2-to-3-day work weeks then. I am shown every day that I have no crystal ball and certainly only hope the current published national inflation rate of 8% doesn’t linger and our slight economic recession doesn’t turn into a full-blown economic downturn.

One item the CLA is working towards publishing is an online inflation calculator, where each individual logging operation can use their own numbers to estimate their own rate, particular to their operating parameters. In doing this, we maintain the strong viewpoint that logging and trucking are completely separate operations, and the costs and variables associated with each need to be calculated and analyzed individually. Doing a few very elementary calculations, I am making a rough “guess” that most logging operations will face annual cost inflation of 10 to 18% this calendar year 2022, with off-road fuel, labor costs, equipment costs, and parts/repairs leading the way. General economic consensus says that capital-intensive businesses with low-profit margins suffer the greatest during high inflation, particularly in tough environments that require frequent equipment replacement.

Watching the Mid-Atlantic fuel pricing, we can easily track what fuel costs have historically been, and the CLA has already published a calculator to aid individual businesses in seeing the effects of cost change. Factor in the impact of social media and an activist liberal government policy towards the labor pool, and you can see what this will do on top of labor costs already adjusted for today’s inflation. Coming off a few years of Covid-related manufacturing slowdown – dealers have no equipment and vehicles to sell – on top of sticking with high initial retail pricing, like any other business, they must find alternative ways to keep the lights on.

Parts sales and labor rates are the obvious targets, and if you are familiar with truck/equipment maintenance and repair at all, then you are acutely aware of the trend away from being able to “do it yourself” and relying heavily on the manufacturer/dealer. This reduces the end user’s ability to control costs directly. A common effect is the “whipsaw” effect, when costs rise quickly, and income is much slower to catch up. Sound familiar?

In the “Great Recession” of 2008-2009, a lot of small businesses survived by putting off capital purchases. Most, including yours truly, learned that this necessity was a bad option – the type of cash flow versus profit margin environment we normally operate in makes a recovery from punting capital purchases down the road option very risky and difficult to see the light again. Loggers’ options for addressing this inflationary period are typical for most small businesses, and they start with knowing where you stand on fixed versus variable (operating) costs. There is not much you can do to change your fixed costs except when it comes time to “renew” these fixed costs. Do you push capital purchases further down the road or take more risks, such as lowering your amount of insurance?

There are more avenues for addressing inflation in the production costs column – such as changing your hours of operation, changing job parameters to work closer to home or shorten skid distance, eliminating any labor buffer of extra employees, etc. I attended an excellent presentation by a representative of a major equipment manufacturer a few weeks ago, and he had numbers to actualize what a lot of us in the industry were already thinking: that for several years now, logging equipment productivity has plateaued.

The equipment’s physical size and operator limitations are two major reasons for this. So, for the last 4 or 5 years, we have already absorbed (without production increases) the large capital increases of annual inflation and mandated technology. Take the Tier 4 emissions systems, which not only add fixed and operating costs but reduce an engine’s achievable lifespan by recirculating “used” air back through it. To summarize this paragraph: if your operation has worked towards efficiency in years past, there is very little a logging operation can do within itself to address today’s inflated costs.

Now to pull out the crystal ball and predict what the future holds. (Who has a lot of confidence in me doing that?). I can give you my one foot in the grave and the other following closely behind a logger’s experience ideas. One scenario is to purely let the market decide what happens. In this scenario, if the economy stays healthy, we’ll whipsaw back and forth between rising costs and catch-up rates until they stabilize. If the economy falters and consuming mills drop production, many loggers will go out. Good ones by decision and poor ones by default. Scenario number two is one I believe loggers should support: a genuine relationship where loggers, procurement foresters, mill representatives, and virtually all involved understand costs, what is happening, and work towards a sustainable forest products industry.

This effort will require somewhat of a paradigm (that’s a $10 word thrown around) shift to include more communication and understanding along with a market economy. Too much to hope for? I hope not, and the CLA is working towards this goal – we are loggers, and we understand our end of the business, but we also recognize we need and ask for input from others in the industry who are interested enough to provide.

So, Mrs. Johnson, if this FRA publication makes it to your retired English teacher’s reading material, please don’t grade it. You cannot take back my diploma. For everyone else: I hope I provided some thoughtful material that contributes to the FRA effort to strengthen this supply chain.

Chip Capps | Arcola Logging Co., Inc. | Board Chairman of the CLA | 2022 FRA Southeastern Outstanding Logger Award Recipient